Mazak VCU-500A 5X CNC

Machining Centers

Price on Request

Product Description

Year: 2014

This Mazak VCU-500A 5X is a versatile vertical machining center designed for high-precision 5-axis machining of complex parts. With 12,000 RPM spindle speed, through-spindle coolant, full probing package, and Mazatrol Matrix 2 CNC control, it offers exceptional accuracy, speed, and productivity for demanding manufacturing environments.

Equipped With:

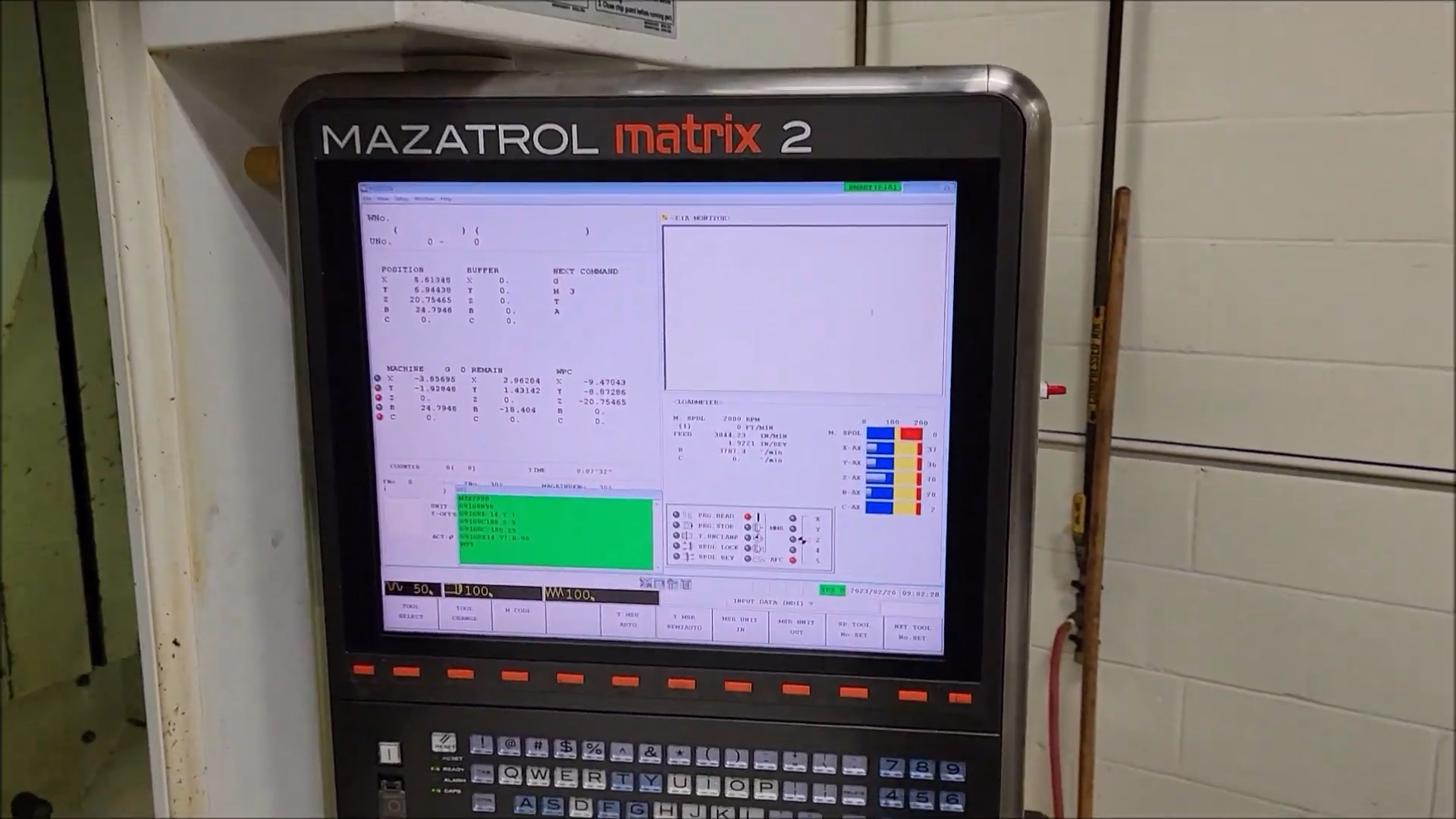

- Mazak Mazatrol Matrix 2 CNC Control

- 500 mm tilting/rotating work table

- 12,000 RPM CAT-40 taper 25 HP spindle

- 213 PSI through-spindle coolant system

- Renishaw tool and part probing system with probes

- 30-station twin arm automatic tool changer

- Remote jog handle

- Spindle chiller

- Jorgensen left-side chip conveyor

- USB & SD card ports

- Workpiece air blast and air-through spindle

- Synchronized tapping

- Advanced compensation functions: EIA dynamic compensation, interpolation, work setting error compensation, tool centerpoint control (5-axis), tool radius compensation (5-axis), shape compensation, G00 slope constant

- Mazak 3D high-speed software and high-smoothing control option

- Coolant system with tank

- Machine manuals

Highlights:

- Full 5-axis machining capability

- Probing and compensation functions for precision part production

- High-speed spindle with through-spindle coolant for efficient cutting

- Robust construction and Mazak’s advanced software for superior finish quality

Condition: Excellent, fully equipped, and ready for production.