Matsuura MX-330 PC10

Product Description

This barely used Matsuura MX-330 PC10 combines high rigidity, excellent accuracy, and full 5-axis capability in a compact footprint. Designed for complex part machining with integrated automation, the PC10 system provides ten automatic pallets for continuous production, making it ideal for medical, aerospace, die/mold, and high-performance industries. Equipped with a 20,000 RPM spindle, 90-tool ATC, and advanced probing systems, this machine delivers unmatched precision and productivity for multi-axis applications.

Key Specifications

-

Year: 2020

-

Travels: X = 18", Y = 17", Z = 22"

-

Spindle: 20,000 RPM, CAT-40 Big Plus, 15/25 HP

-

Tool Changer: 90-position ATC

-

Pallet System: 10-position PC10 automatic changer

-

Max Workpiece Size: Ø330 × H300 mm (Ø12.99" × H11.81")

-

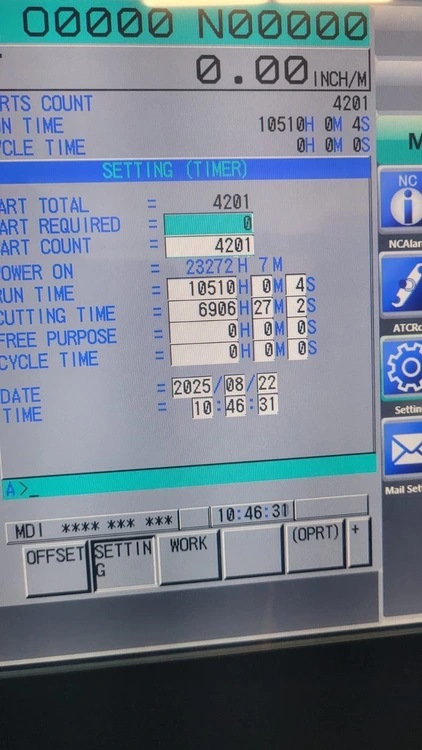

Control: Matsuura G-Tech 31i CNC

-

Coolant: Thru-spindle, 300 PSI with filtration

Equipped With

-

Matsuura G-Tech 31i CNC Control

-

20,000 RPM Air/Oil Spindle

-

90-Tool Automatic Tool Changer

-

10-Station Automatic Pallet Changer (PC10)

-

LNS Turbo Micro-Hinge 250 Chip Conveyor (rear discharge)

-

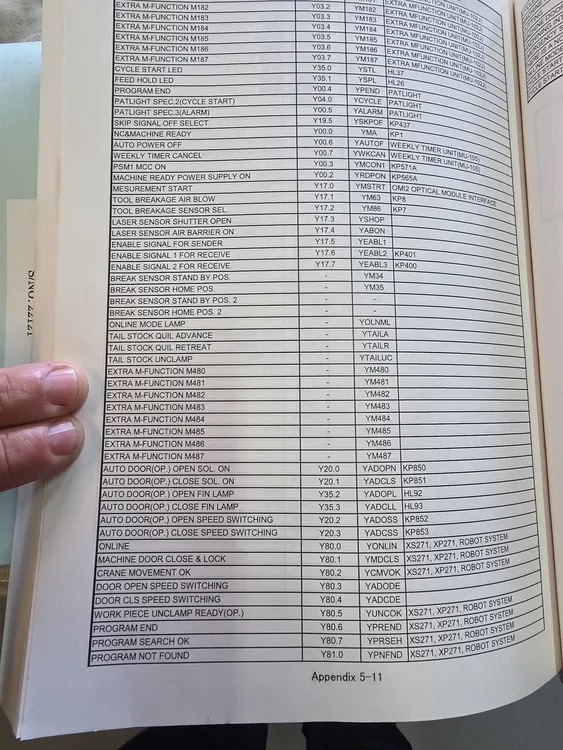

Renishaw OMP-60 Part Probe & NC-4 Laser Tool Measurement

-

High-Pressure Coolant Pump (300 PSI) with fine filtration

-

Environmental thermal compensation package

-

Mist collector and air dryer

-

Complete simulation and verification software

-

Four (4) additional MX-330 PC10 pallets

Highlights

-

True 5-axis machining with integrated automation

-

High-speed 20,000 RPM spindle for demanding materials

-

Extended unmanned operation with 10-pallet changer

-

Equipped with advanced probing and thermal compensation for precision