Mazak Integrex i-400 ST 5-Axis

Product Description

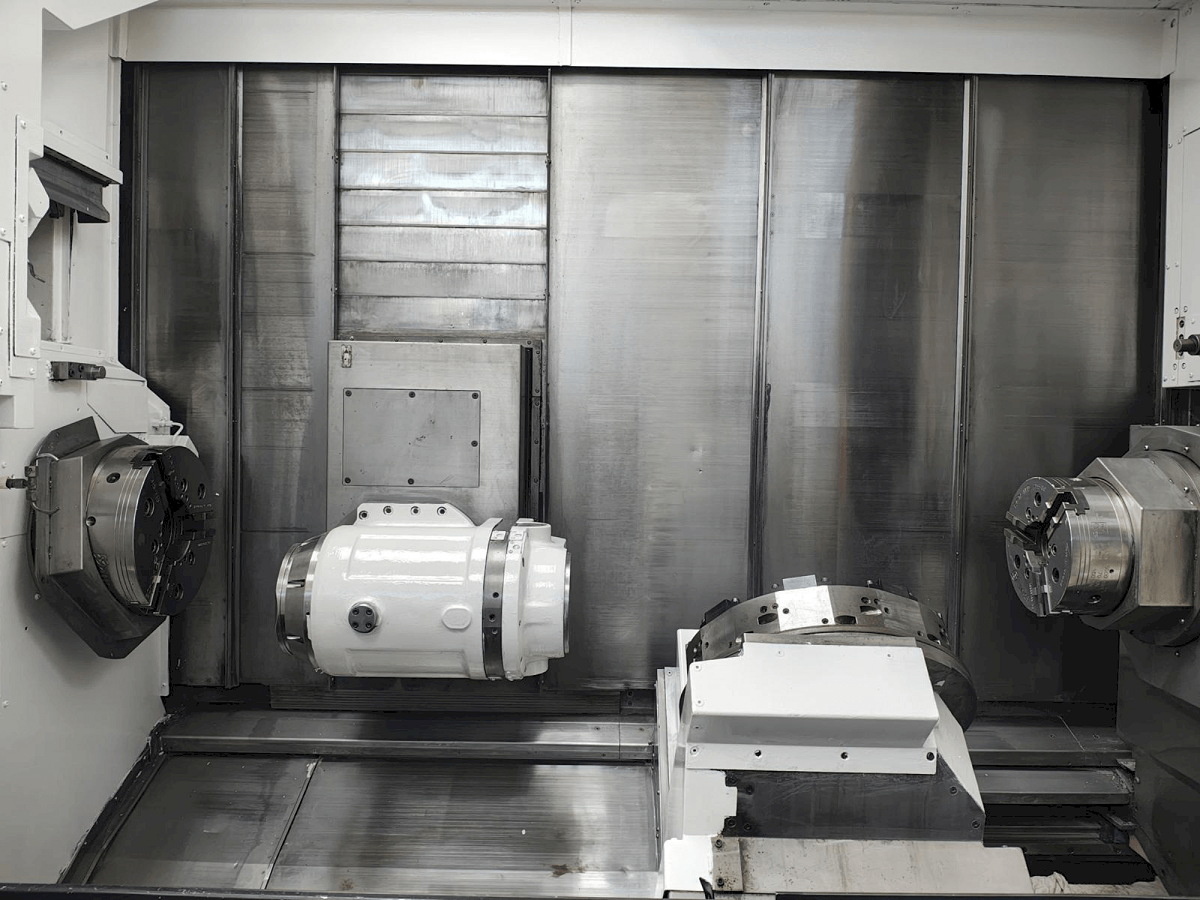

High-performance multi-tasking CNC turn-mill center designed for complete machining of complex components in a single setup. The Mazak Integrex i-400 ST combines full 5-axis milling capability with twin spindles and a lower turret for maximum flexibility and productivity. Equipped with MAZATROL Matrix 2 control and high-pressure coolant systems, it is ideal for demanding aerospace, energy, and precision engineering applications.

Technical Specifications

-

Manufacturer: Mazak

-

Model: Integrex i-400 ST

-

Year: 2014

-

Type: 5-Axis Turn-Mill Centre

-

Control: MAZATROL Matrix 2

-

Number of Axes: 5

-

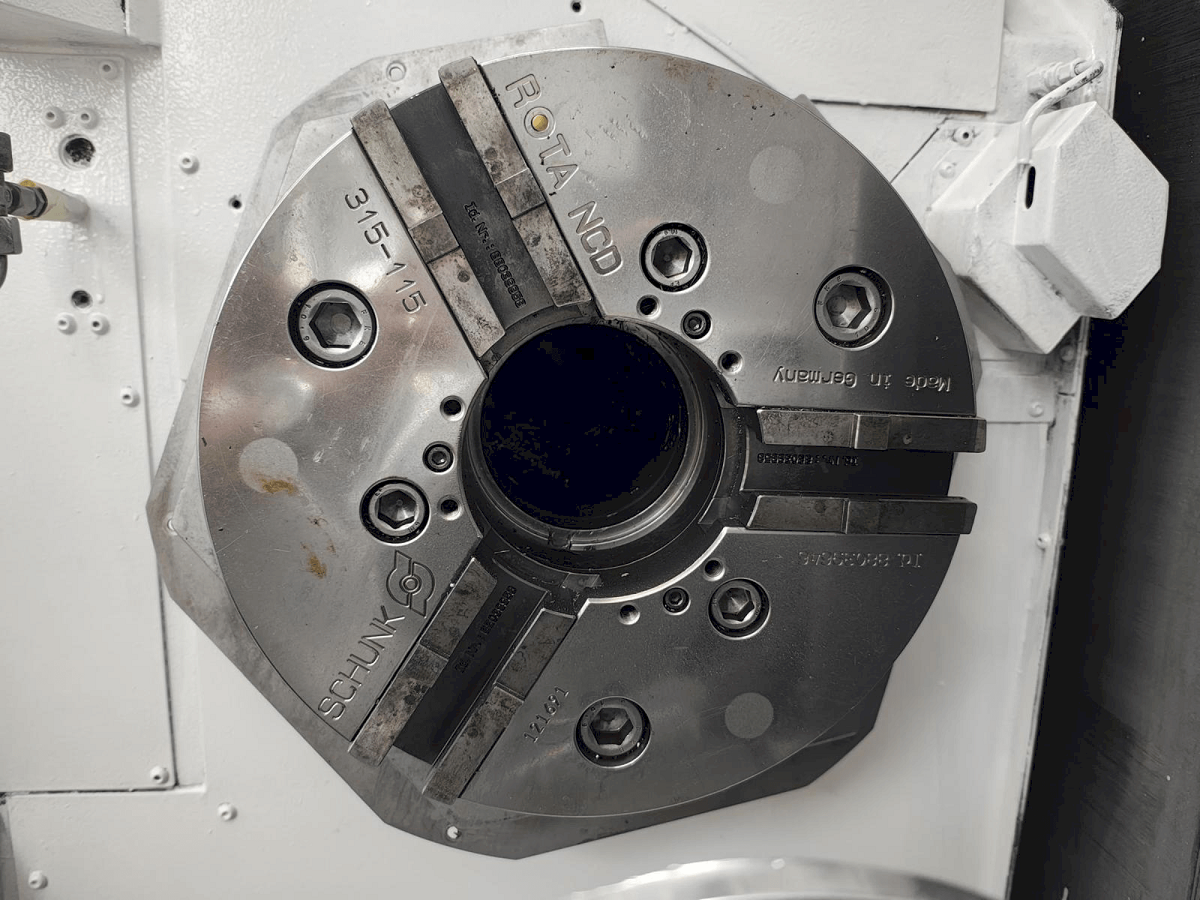

Main Spindle Bar Capacity: 102 mm

-

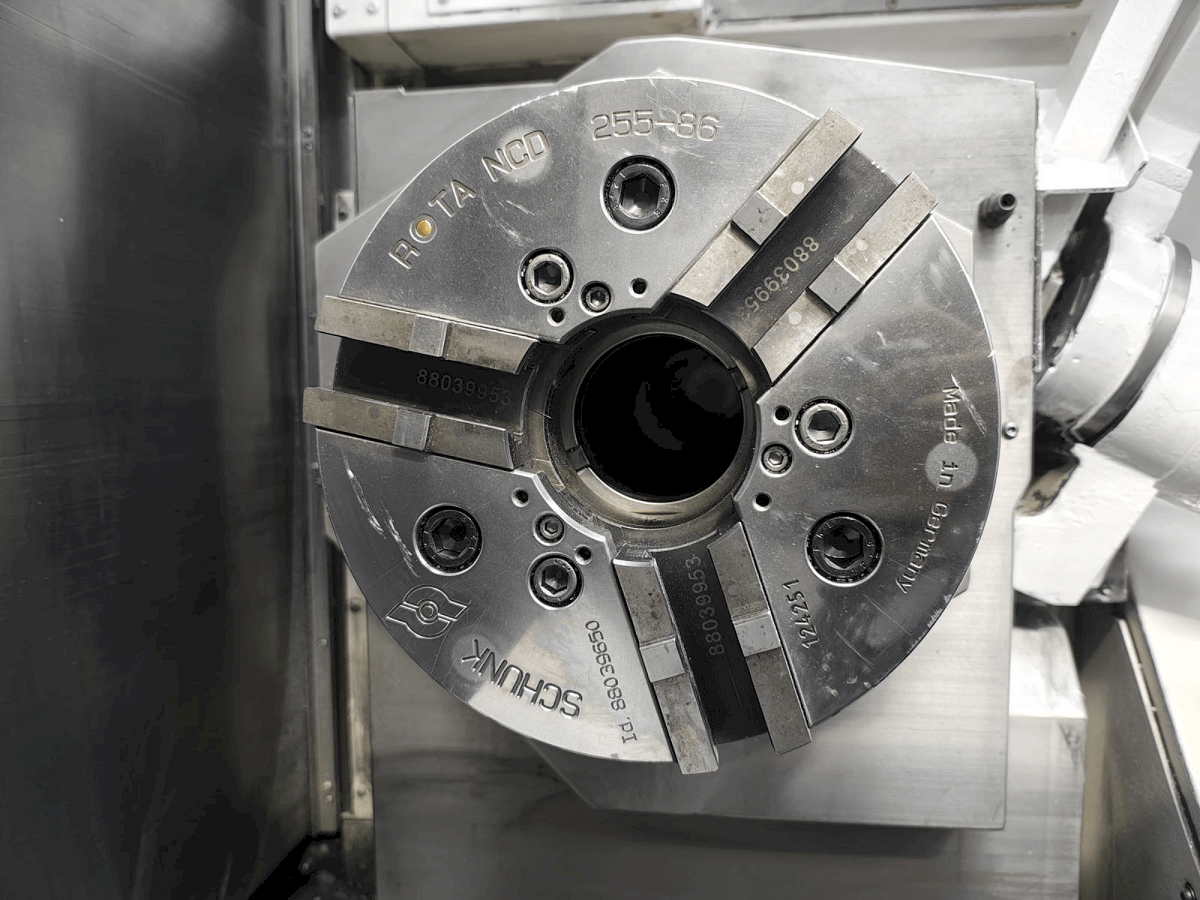

Sub-Spindle Bar Capacity: 80 mm

-

Main Spindle Motor Power: 30 kW

-

Sub-Spindle Motor Power: 26 kW

-

Maximum Milling Spindle Speed: 12 000 RPM

-

Y-Axis Travel: 260 mm

-

Z-Axis Travel: 1 585 mm

-

W-Axis Travel (sub-spindle): 1 539 mm

-

X2-Axis Travel (lower turret): 230 mm

-

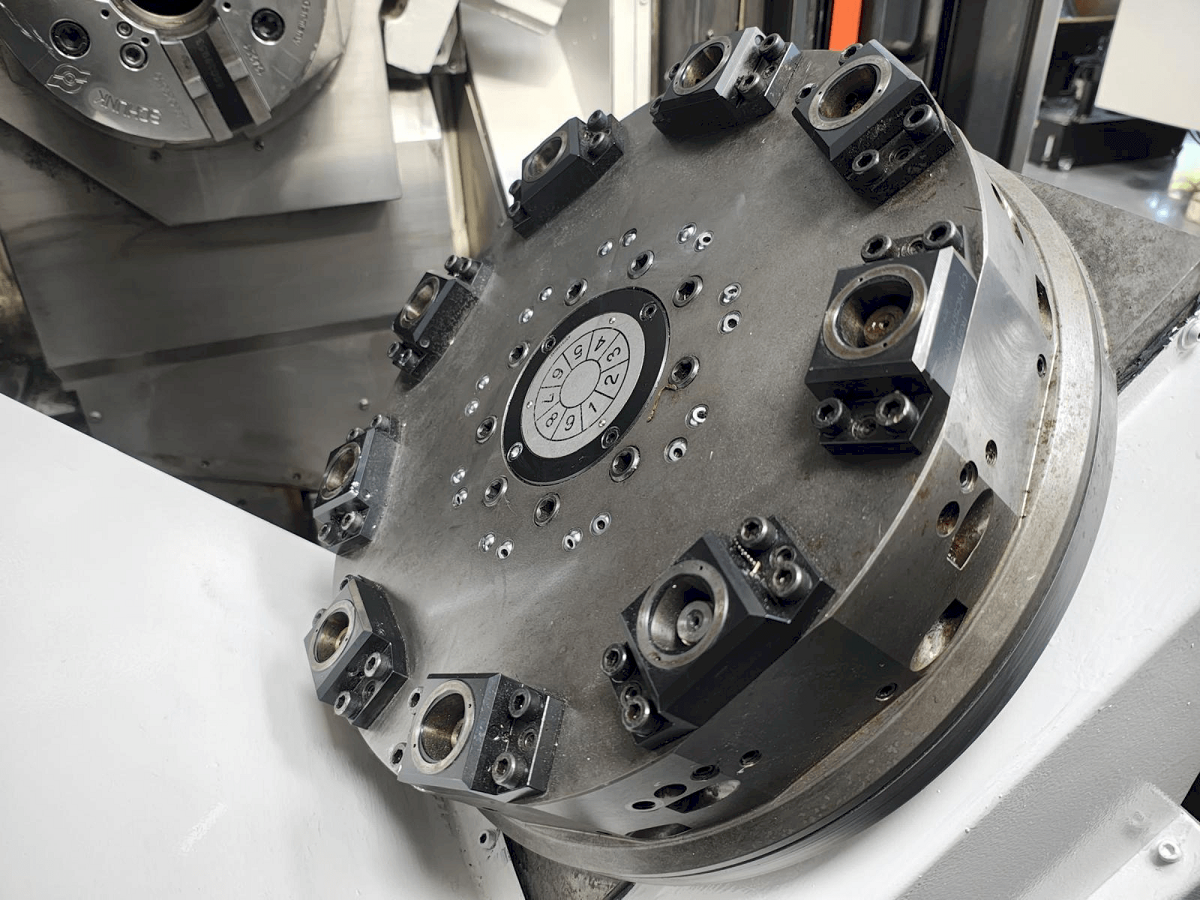

Number of Turret Tools: 9 positions (Capto C4 interface)

-

Coolant Pressure: up to 70 bar

Equipped With

-

MAZATROL Matrix 2 CNC control

-

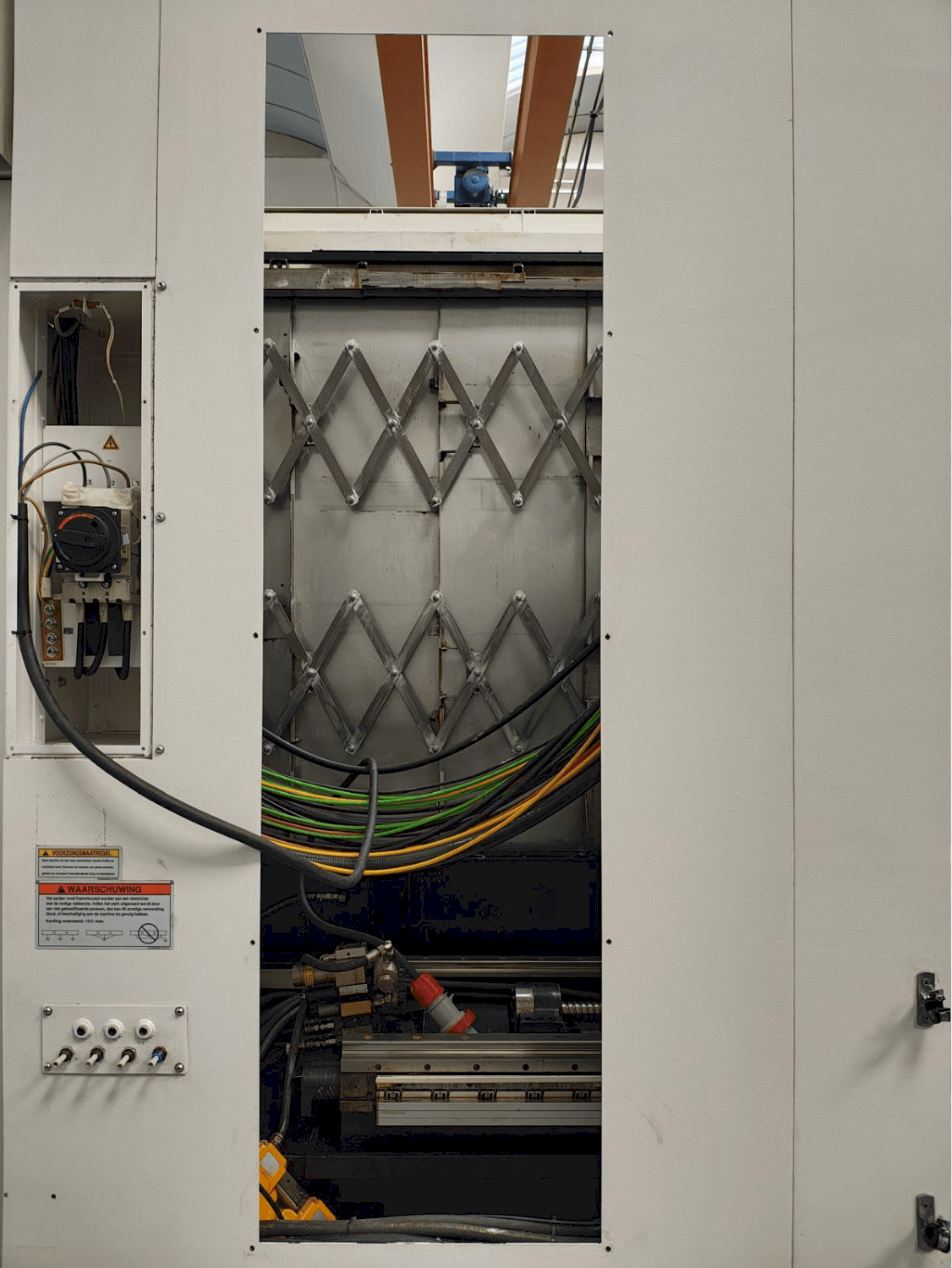

Automatic doors

-

Robot interface for automation integration

-

High-pressure external coolant tank (70 bar)

-

Renishaw probe

-

Tool chip reader

-

Lower turret with Capto C4 tooling

-

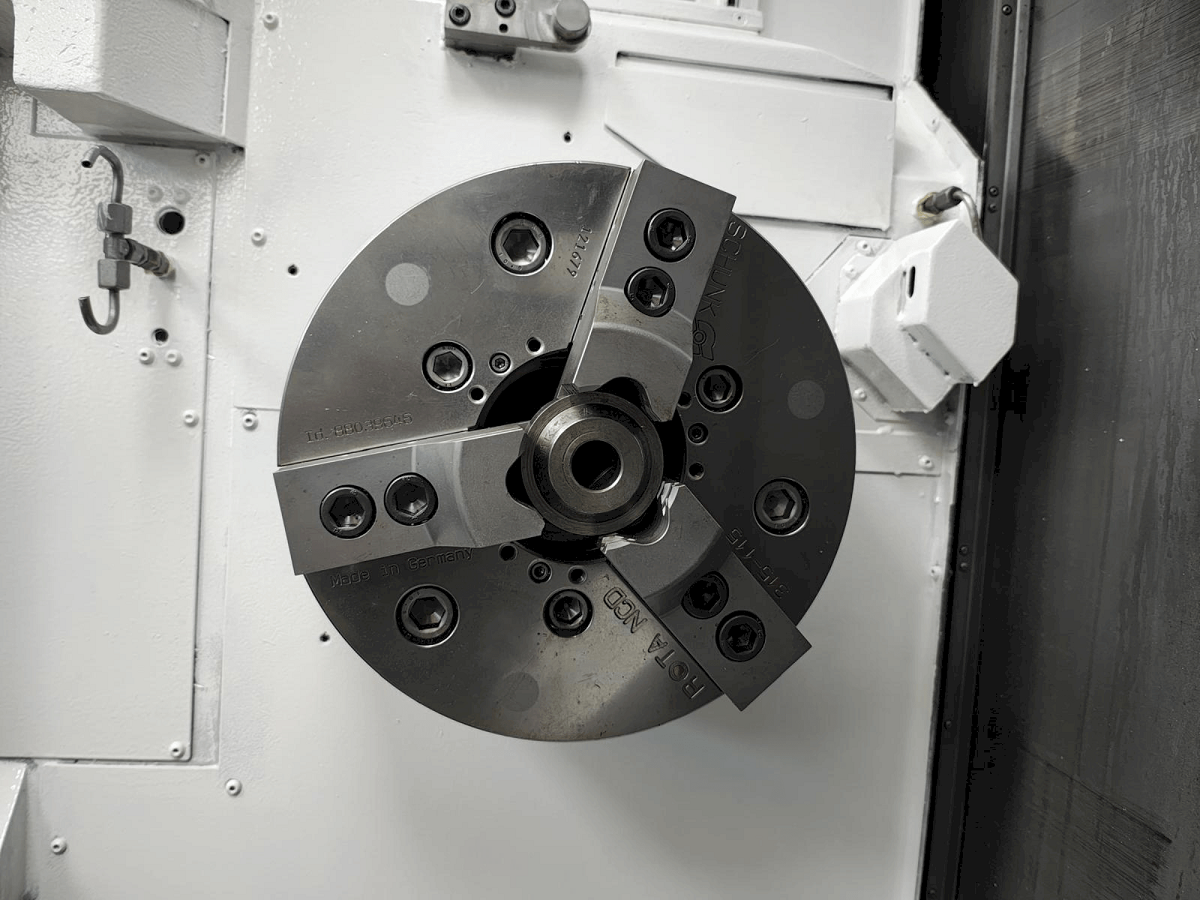

Twin-spindle configuration for done-in-one machining

-

Chip conveyor

Condition

-

Good working condition, well-maintained

-

Fully operational and equipped for multi-axis, multi-process machining

-

Ready for immediate use in high-precision, high-efficiency production